Burner Management Systems

Ensuring Operational Excellence:

CanCat Tech, your partner for safe and reliable burner management solutions.

CanCat Tech designs, and supplies cutting edge Burner Management Systems (BMS) tailored to the specific needs of the industrial combustion market. With a wealth of expertise in combustion technology and safety standards, CanCat Tech delivers comprehensive solutions that ensure optimal performance, safety, regulatory compliance, and peace of mind for your industrial heating processes.

Our BMS solutions integrate the most robust hardware components, and intuitive user interfaces to effectively manage burner operations while minimizing risks and maximizing productivity. From concept to commissioning, the CanCat Tech team works closely with our clients to capture their requirements and develop customized BMS solutions that meet or exceed industry standards.

A Burner Management System (BMS) is a Safety Instrumented System (SIS) used to ensure the safe start-up, operation, and shutdown of fuel handling and burning equipment and also prevents mis-operation and damage to fuel preparation and burning equipment. Burner Management Systems play a critical role in various industries where industrial burners, furnaces, boilers, or other combustion equipment are used.

A BMS is comprised of the following components:

Functions of a BMS:

Startup

When safety-related requirements are not fulfilled, the BMS prevents the burner from starting.

Monitoring

It continuously monitors the burner to identify potentially dangerous operating scenarios.

Shutdown

The BMS protects against unsafe conditions by shutting down the burner(s) when unsafe process conditions arise.

Component Sequencing

The BMS ensures that the system components are sequenced correctly during startup and shutdown.

Operator and Feedback

In unfavorable operating circumstances, the BMS can be designed to trigger a Master Fuel Trip (MFT) and provides annunciation for operator action.

Advantages of a BMS:

Worker Safety

Creates a safe environment for workers near fuel burning equipment.

Equipment Safety

Ensures safe burner operation, preventing hazardous conditions and providing protection for plant assets from operational damage.

In processes where there is no mechanical layer of protection, the BMS is the last line of defense. Having knowledge of this, CanCat Tech applies the IEC 61511 Safety Lifecycle for BMS analysis and design to ensure the most robust and reliable product. Our SIS designers have met the required competency level usually demanded by industry, our customers and governing bodies, through certifications such as:

- TÜV Functional Safety (SIS) Certificate

- Certified Functional Safety Expert (CFSE) or Certified Functional Safety Professional (CFSP) Certificate (administered by Exida)

- ISA S84 SIS Fundamentals Specialist and ISA S84 Safety Integrity Level Selection Specialist certificate

Our design team works with a wide range of design codes and standards including:

- API 538, 556

- CSA B149.3

- EN 13611 and EN 298

- IEC 61511, 61508

- ISA 61511

- NFPA 85, 86

Canadian Catalyst Technologies has decades of experience, designing and providing Burner Management Systems to the international market on all major logic solver platforms.

Experience

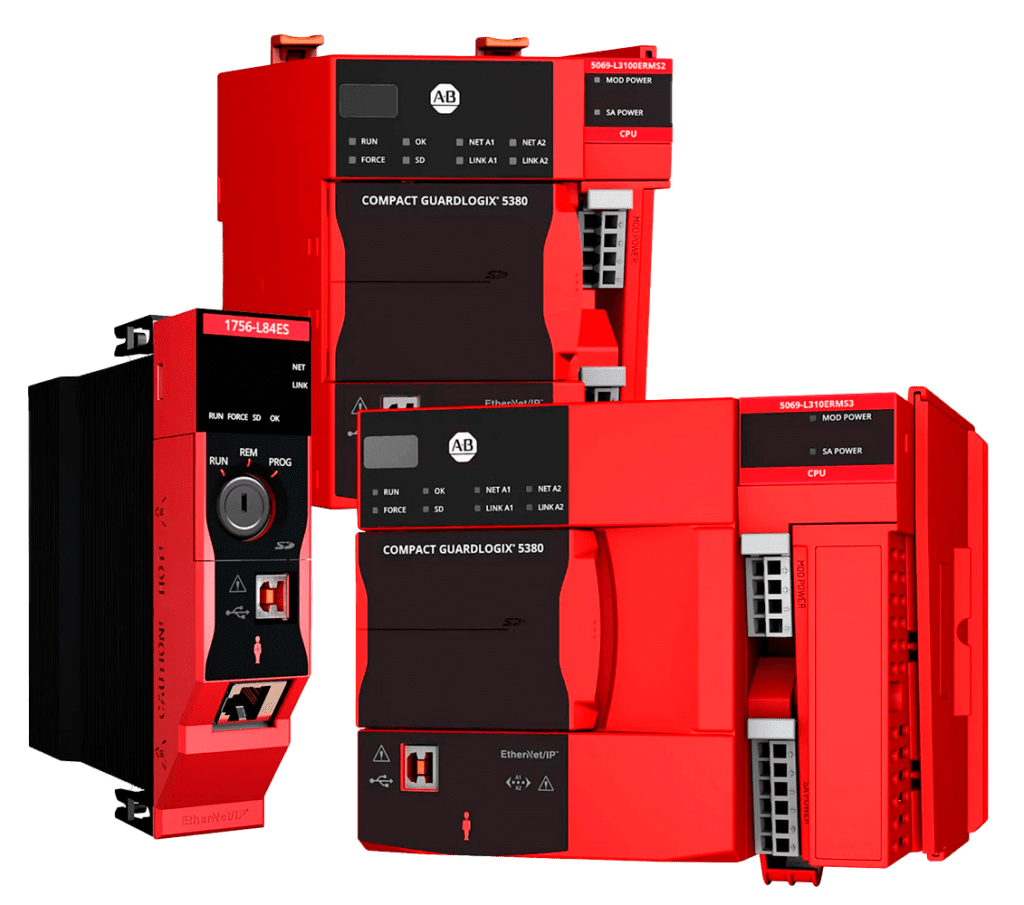

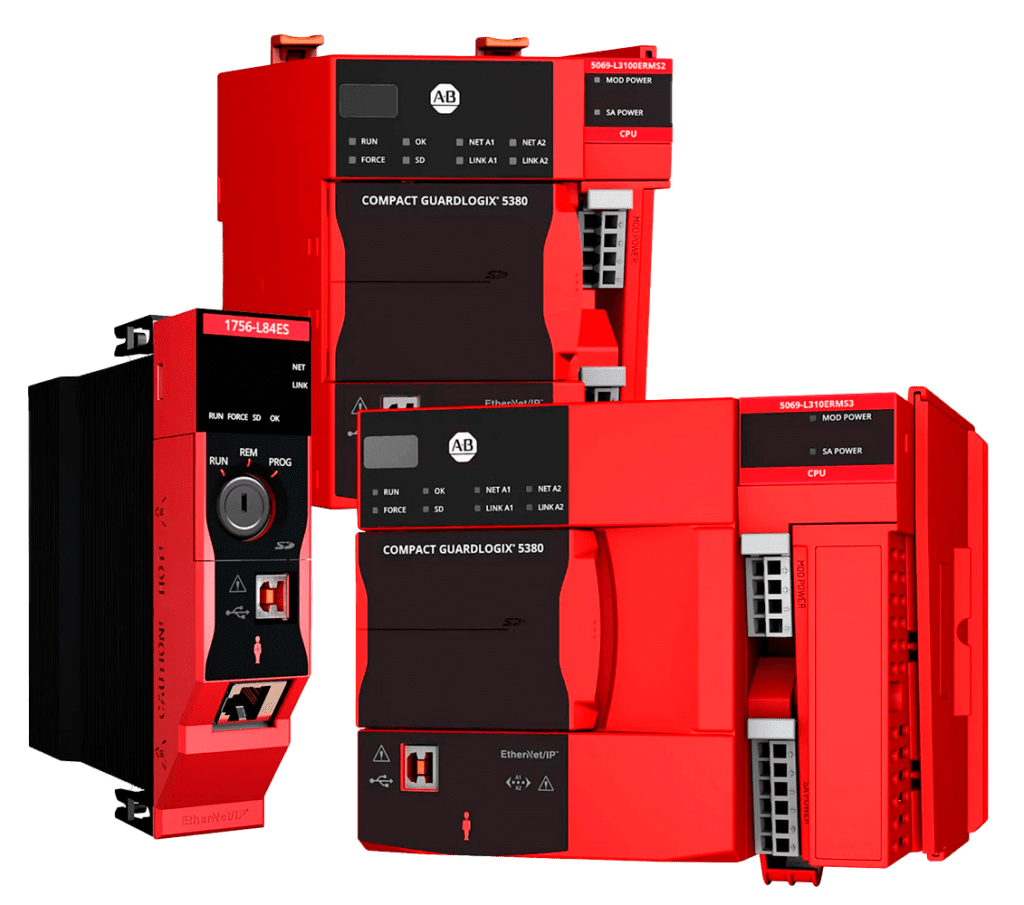

The CanCat Tech team has successfully designed, constructed and commissioned Burner Management Systems on all major Logic Solver Platforms, including:

- Rockwell Automation Control GuardLogix

- Rockwell Automation AADvance Safety System

- Schneider EcoStruxure™ Triconex® - Tricon CX

- Schneider EcoStruxure™ Modicon M580 Safety

- DeltaV SIS™ with Electronic Marshalling

- Siemens Simatic PCS 7

- Siemens Simatic S7 (F - Fail Safe)

- Honeywell SLATE™

CCT SIS designers utilize the IEC 61511 Safety Lifecycle for BMS analysis and design to ensure a very robust product.

Our supply of BMS equipment and services range from “packaged solutions” to stand-alone panels for upgrades such as:

- Green Field CapEx Projects

- Brown Field Furnace Replacement Projects

- Safety System Modernization

- Emissions Improvement + Decarburization Projects

- Relay Based Hardwired BMS Upgrades/Retrofit to Programmable Electronic Solution

BMS Services Offered

Canadian Catalyst Technologies offers services for design, construction and commissioning of BMS for new and existing processes.

Our deliverables can include:

- Detailed Bill of Materials

- Electrical Schematics

- Control Panel Layout

- Junction Box Drawings & List

- Instrument Loop Drawings

- Instrument I/O List/Index

- Sequence & Control Narratives

- Cause & Effect Matrices

- Factory Acceptance Test Report

- Customer Specific Documentation

Canadian Catalyst Technologies Corp. is a vertically integrated, employee-owned subsidiary of a well-established Canadian design and manufacturing company specializing in welding and fabrication services, known for its expertise and quality craftsmanship in the industry. With a rich heritage in industrial combustion and thermal processing, we offer a comprehensive range of thermal products and services, including feasibility engineering, detailed engineering and design, manufacturing, installation support as well as commissioning and start-up services.

Get In Touch

- 1399 Advance Road

- Oakville, Ontario Canada L6L 6L6

- Office: (365) 367-1673

- inquiries@cancattech.com